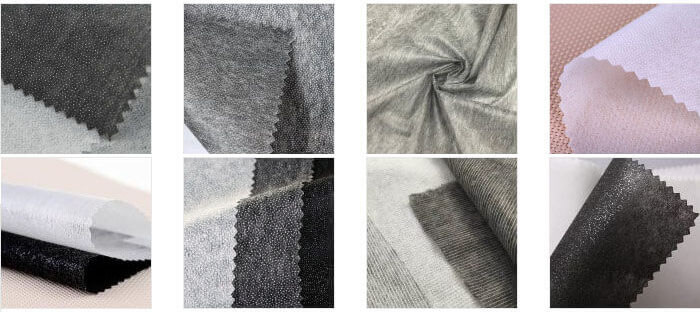

Woven interlining and non woven interlining.

Interlinings can be divided into two categories generally: woven interfacing and non woven interfacing.

1. Non Woven Interlining, as just its name. It is fabric without textile or weave.

Technical as following:

The chemical fiber with viscose form the base fabric under high temperature and high pressure. Then the coating machines scatter hot melt adhesive on the surface of base fabric, after dry process, non woven fusible interfacing formed.

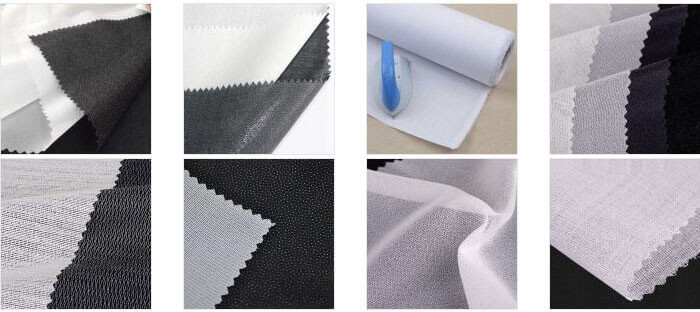

2. Woven Interlining including woven fusible interfacing and knitted fusible interfacing. Knit lining is divided into warp and weft woven interlining.

Woven interlining is suitable for knitting, silk, woolen fabrics; used in the clothing predecessor, cuffs, collar and other parts. It make the perfect shape to show the clothing apparel elegant style.

In summary, non woven interlining is cheaper than woven interfacing, but woven has strong tension and elastic.